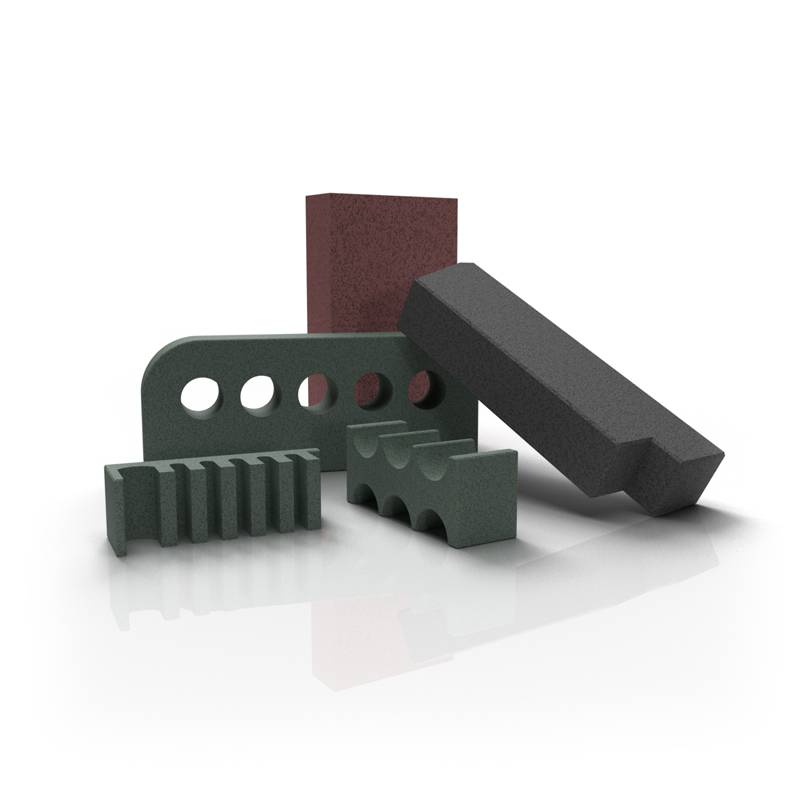

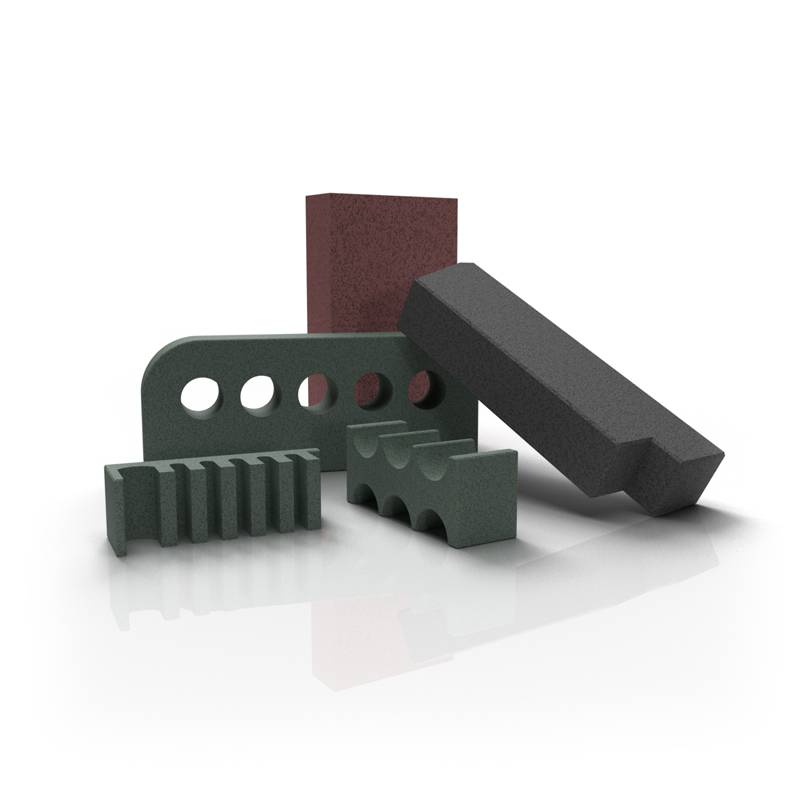

FLAMMADUR® F 500 can be moulded into bricks, sheets, strips, plugs or other shapes for various fire-stopping applications, including self-adhesive types. For special requirements it is also possible to get FLAMMADUR® F 500 in complex forms, in combinations with other surfaces and construction materials or in self-adhesive types.

FLAMMADUR® F 500

Moulded parts

In the event of a fire, FLAMMADUR® F 500 forms a heat-insulating foam and fills joints, gaps as well as other openings, thus preventing the passage of heat. FLAMMADUR® F 500 is a ready-to-use intumescent sealing system consisting of flexible polyurethane foam. It is designed for fireproofing cable and pipe penetrations in rolling stock. The system can be individually adapted to suit specific customer needs. A wide variety of moulded parts, including complex mouldings, can be customised depending on customer requirements and on-site conditions.

Field of Application

- Internal applications

- Cable management

- On request

Certification

- ETA-17/0022

- The product meets requirements R22 / R23 for hazard levels HL1 – HL3 as per DIN EN 45545-2 (02/2016)

- DMT test report No. 20666901-40

Downloads

Datasheets

Technical Data Sheet FLAMMADUR® F500Container and Packaging Sizes

Rolling Stock - Container and Packaging SizesTest reports

DIN EN 45545-2 - FLAMMADUR® F500 - DE-EN Further reports on requestField of Application

Product features

- Colour: adjustable

- Fibre and solvent-free

- When exposed to thermal influence from a fire, the material forms a heat-insulating foam layer

- Fast response time

- Density: adjustable

Handling

- FLAMMADUR® F 500 must not be exposed to direct atmospheric impact, such as driving rain, freeze-thaw alternation or UV radiation.

- If the site of installation is such that the building material will be exposed to special stress, e.g. to the constant influence of chemicals or aerosols, supplementary evidence must be furnished.

- The substrate must be free of contamination.

- The sealing compound is obtained by carefully mixing the hardener component into the resin.

- Neither the components nor the uncured mixture must be allowed to come into contact with any type of humidity. Humidity can produce unwanted chemical reactions, it causes the material to foam up and affects its properties.

Classifications

- The product meets the requirements of R22 / R23 for hazard levels HL1 – HL3 in acc. with DIN EN 45545-2 (02/2016)

DMT PB-Nr. 20666901-40