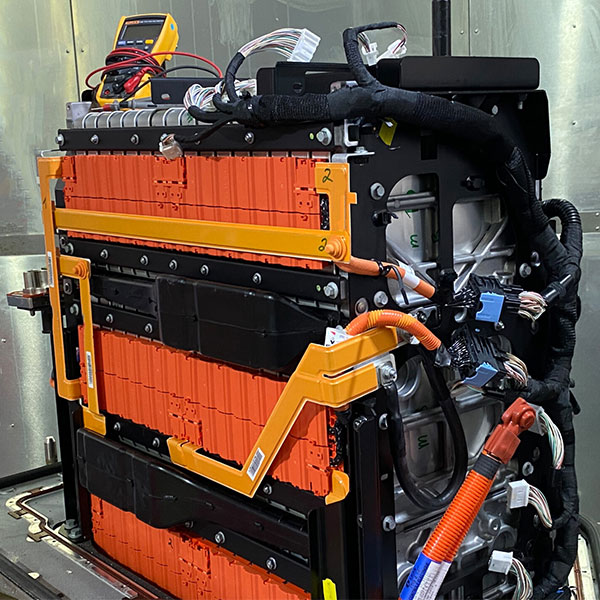

Seevetal, 05.07.2021: svt Products and TÜV Rheinland ACT have embarked on a cooperation to test the safety of battery storage systems for electromobility applications. Drawing on their combined expertise, the two cooperation partners offer a unique range of fire protection testing services at the new battery test centre of TÜV Rheinland ACT located in Aachen, Germany. On behalf of manufacturers, svt fire protection components for battery storage systems will be developed to the point of marketability, further to which they will be tested and certified in accordance with the pertinent national and international standards. The test centre in Aachen is equipped to induce thermal runaway events in battery systems in a controlled environment, with a view to ascertaining the effectiveness of the fire safety means and measures employed.

svt Products brings to the collaborative partnership its extensive professional expertise in passive fire protection, with a special focus on solutions in the field of battery safety, while TÜV Rheinland ACT contributes at its Aachen location the specialist know-how of its well-established experts along with testing resources and a wide range of testing services revolving around battery technology. The joint effort of svt Products and TÜV Rheinland ACT is geared to maximising the reliability and performance of fire protection systems throughout the entire battery lifecycle. The safety of the systems developed by svt is ensured by means of extensive fire tests conducted at Germany’s most advanced test centre in accordance with a variety of different national and international regulations and standards. Once expansion of the Aachen site is complete in 2022, it will be equipped for testing even larger battery systems with capacities of at least 150 kWh, dimensions of at least 2.3m x 1.6m x 0.4m and a weight of approx. 800 kg.